Tuam Tshoj polycarbonate vov tsev ntawv tsev cog khoom polycarbonate ntawv manufacturers thiab lwm tus neeg |JIAXING

Thickness

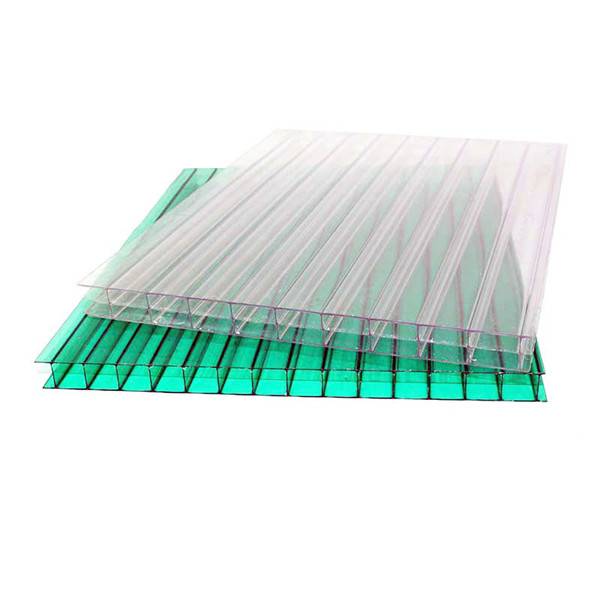

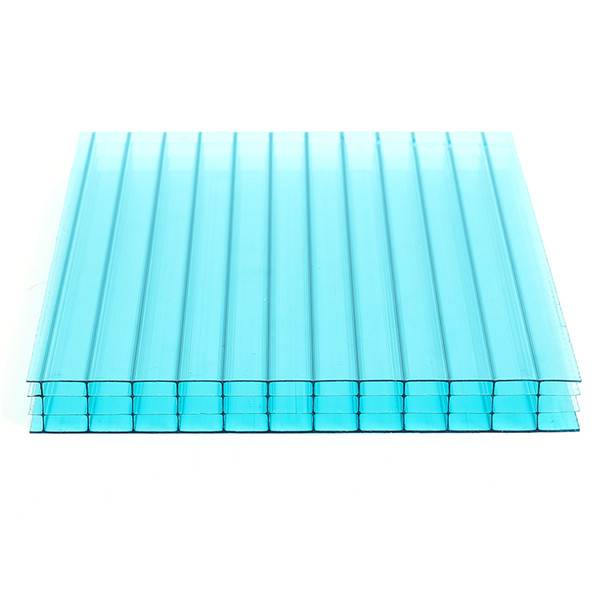

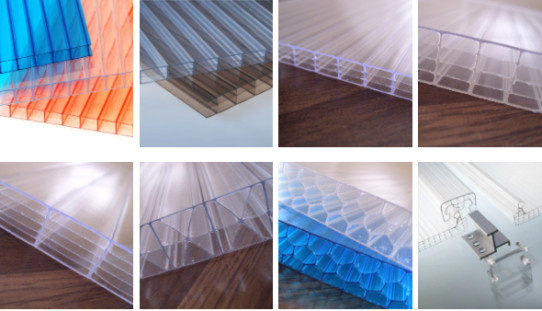

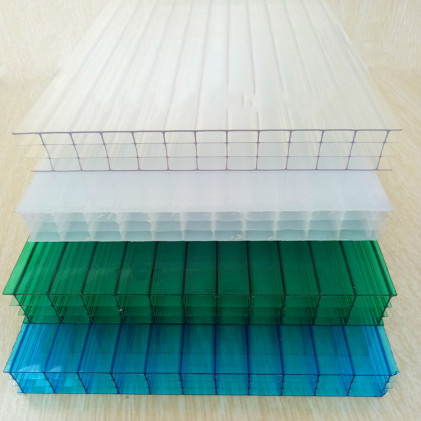

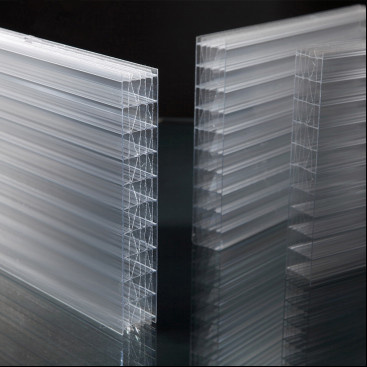

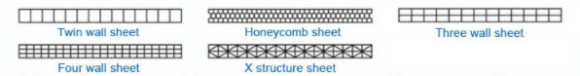

(1).Twin-walls polycarbonate ntawv thickness: 4mm, 6mm, 8mm, 10mm, 12mm, thiab lwm yam.

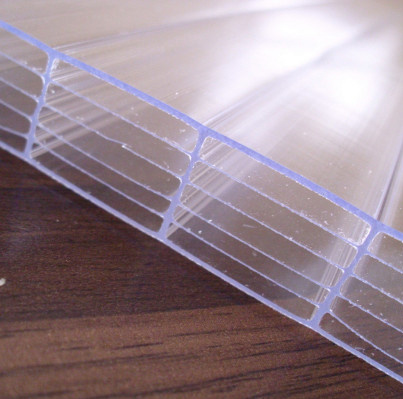

(2).Triple-walls polycarbonate ntawv thickness: 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, thiab lwm yam.

(3).Plaub-phab ntsa polycarbonate ntawv thickness: 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, thiab lwm yam.

(4).Tsib-phab ntsa polycarbonate ntawv thickness: 8mm, 10mm, 12mm, thiab lwm yam.

(5).Rau phab ntsa polycarbonate ntawv thickness: 16mm, 20mm, 25mm, thiab lwm yam.

(6).X-Profile polycarbonate ntawv thickness: 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, thiab lwm yam.

(7).Honeycomb polycarbonate ntawv thickness: 6mm, 8mm, 10mm, 12mm, thiab lwm yam.

Dav: 1220mm, 2100mm

Ntev: Tsis muaj kev txwv (pom zoo 5800mm, 6000mm, 11800mm, 12000mm kom haum 20' thawv & 40' thawv)

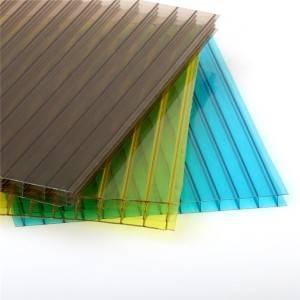

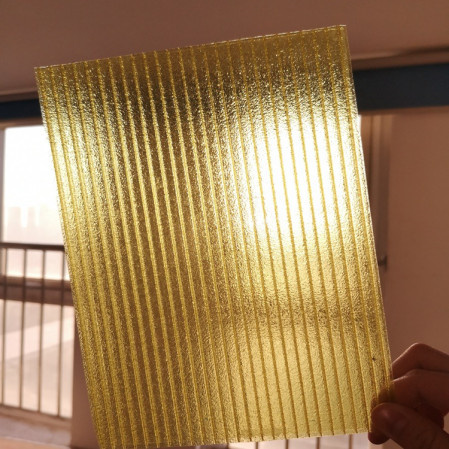

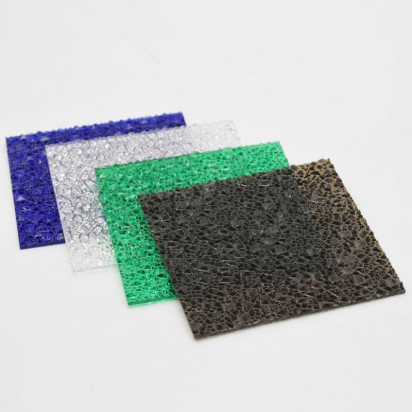

Xim: ntshiab / pob tshab, pas dej xiav, ntsuab, xiav, opal, dawb, xim av/bronze, silvery grey, liab, daj, thiab lwm yam.

| Cov ntaub ntawv technical (ob phab ntsa polycarbonate hollow ntawv) | ||

| Yam ntxwv | Chav tsev | Cov ntaub ntawv |

| Kev cuam tshuam lub zog | J/m | 2.1 |

| Lub teeb kis tau tus mob | % | 50-85 : kuv |

| Qhia lub ntiajteb txawj nqus | g / m | 1.2 |

| Coefficient thermal expansion | mm/m ℃ | 0.065 ib |

| Kev pabcuam kub | ℃ | -40 ℃ ~ + 120 ℃ |

| Thaum tshav kub kub conductive | W/m² ℃ | 3.0-5.0 Nws |

| Flexural zog | N / mm² | 100 |

| Modulus ntawm elasticity | Mpa | 2400 |

| Suab rwb thaiv tsev nyhuv | db | 20 decibel txo rau 10 hli pc ntawv |

| Tensile zog | N / mm² | ≥60 |

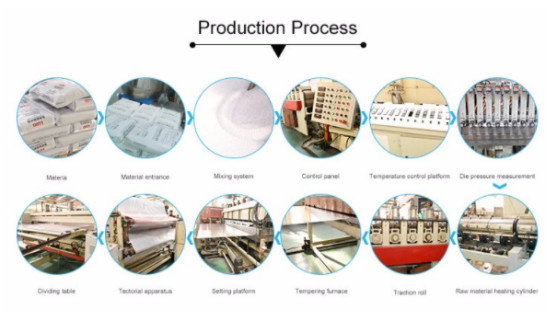

Cov ntaub ntawv xeem

| Fiberglass | Taishan E-iav | Anti-UV | ≥99% |

| Qhov hnyav | 1.4kg / m2 / hli | Kub Tolerance | -20ºC txog 80ºC |

| Txuj kev tsim khoom | GB / T-14206 | Shear Strength | 92 MPa ua |

| Tensile zog | 75 MPa ua | Flexural zog | 110 MPa |

| Thermal conductivity | 0.158 W/M·K | Thermal Expansion Coefficient | 2.55 x 10-5 cm / cm / ºC |

Khoom Xim

Khoom Muag Khoom

1. Lub teeb kis tau zoo heev, txog li 18% -80%

2. Polycarbonate yog feem ntau poob siab-resistant polymer engineering yas, uas yog 10-27 lub sij hawm siab tshaj plexiglous iav thiab yuav tsis tig daj nyob rau hauv lub hnub.

3. Qhov saum npoo muaj 50 micron los tiv thaiv ultraviolet txheej, 10 xyoo kev lees paub zoo, yuav tsis ua rau yellowing

4. Qhov kub ntawm -40 ℃ thiab + 120 ℃ yuav tsis ua rau deformation thiab lwm yam tsis zoo

5. Lub teeb yuag, yooj yim thauj thiab nruab

Yam khoom kos duab

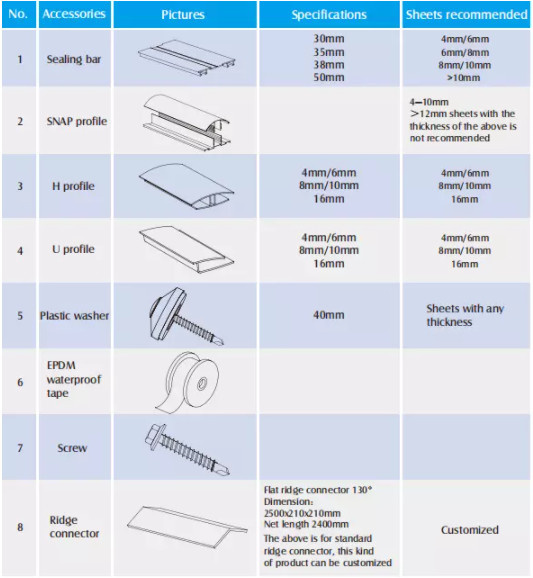

Accessories